Step-by-Step Overview to Preventing Weld Undercut in Different Metals

Step-by-Step Overview to Preventing Weld Undercut in Different Metals

Blog Article

Essential Tips for Welders: Avoiding Undercut Welding and Ensuring Stronger Weld Joints

In the world of welding, attaining strong and long lasting weld joints is the keystone of creating high-quality work. One common obstacle that welders often experience is undercut welding, which can endanger the stability of the weld joint. By recognizing the variables that add to undercutting and implementing the right strategies and precautions, welders can properly prevent this issue and guarantee the longevity and stamina of their welds. Let's discover some important pointers that can assist welders navigate this challenge and boost the quality of their welding projects.

Understanding Undercut Welding

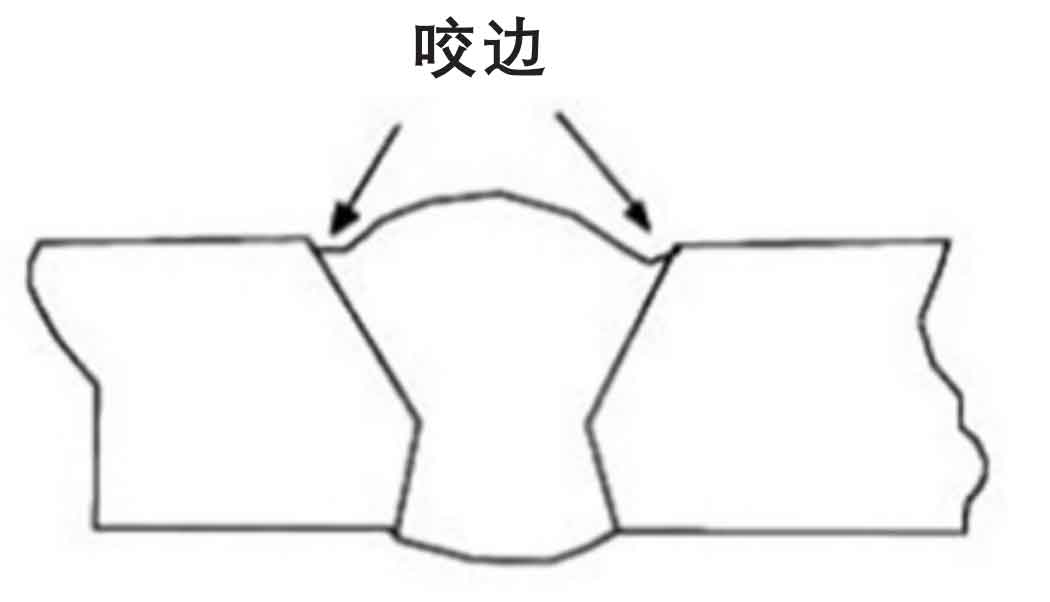

Undercut welding is a common welding defect that happens when the weld metal stops working to properly load the groove and leads to a groove-like clinical depression along the weld bead. This issue damages the weld joint, making it prone to fracturing and failing under anxiety. Undercutting can be triggered by various factors, including excessive welding present, high welding rate, incorrect electrode angle, inaccurate electrode dimension, and poor welding method.

One of the primary factors for undercut welding is a discrepancy in between the welding existing and the welding rate. If the welding current is too expensive or the welding speed is as well quickly, the weld metal might not appropriately fill up the groove, leading to damaging. Furthermore, making use of an electrode that is also large can result in a similar result, as the excess steel can not properly stream into the groove.

To protect against undercut welding, welders ought to ensure they are utilizing the appropriate welding specifications, maintain a suitable electrode angle, select the appropriate electrode size, and method appropriate welding strategies. By dealing with these aspects, welders can minimize the risk of undercutting and develop more powerful, more trustworthy weld joints.

Appropriate Welding Strategy

Effective welding method plays an important role in guaranteeing the top quality and integrity of weld joints. Proper welding method includes a combination of adherence, precision, and ability to finest methods. One fundamental element of proper welding strategy is preserving the right angle and distance between the welding weapon and the work surface. Welders need to likewise pay attention to the traveling speed and warm input to prevent issues like damaging, porosity, or insufficient blend.

In addition, a constant and constant hand movement is vital for developing solid and sturdy weld joints. Welders should go for smooth, uniform movements to guarantee also circulation of the weld product. Correct adjustment of the welding gun and filler product is also essential to achieving ideal penetration and combination.

Additionally, managing the heat input and choosing the ideal welding parameters based on the product being welded are important factors in accomplishing high-grade welds - Preventing weld undercut. Welders need to follow the recommended settings provided by welding procedure specs and change them as needed based upon the certain demands of the project. By understanding proper welding techniques, welders can significantly improve the stamina and reliability of their weld joints

Selecting the Right Electrode

Maintaining the proper angle and distance in between the welding gun and the work surface is fundamental when thinking about the relevance of picking the ideal electrode in welding applications. The option of electrode plays a critical duty in establishing the top quality and strength of the weld joint. Electrodes can be found in various types, each designed for specific functions and materials.

To start with, choosing the suitable electrode diameter is vital. Thinner electrodes are ideal for welding thin materials, while thicker electrodes are better for thicker materials and greater warmth applications. Matching the electrode size to the thickness of the workpiece assists accomplish a well balanced weld.

Secondly, recognizing the material structure of the electrode is crucial. Different electrodes are made for welding particular materials like steel, stainless-steel, light weight aluminum, or cast iron. Utilizing the right electrode product ensures good blend and lessens the threat of issues in the weld.

Last but not least, taking into consideration the welding placement and method is essential when choosing the electrode type. Particular electrodes are much better suited for vertical or above welding click this placements, while others work well for flat or straight placements. Picking the appropriate electrode based upon the welding method improves the total weld quality and integrity.

Preparing the Base Steel

To guarantee a successful welding procedure, what initial steps should be taken when preparing the base steel for welding? Furthermore, any kind of existing weld product or residue from previous welding ought to be eliminated to ensure a tidy surface area for the brand-new weld.

Performing Post-Weld Assessments

After conducting these assessments, welders must compare the outcomes versus market requirements and project requirements to guarantee that the weld joint fulfills all needed criteria. Any deviations or insufficiencies found throughout the post-weld evaluation should be immediately dealt with with suitable restorative measures to assure the weld's integrity. By diligently carrying out post-weld evaluations and try here promptly attending to any concerns, welders can maintain the high quality and integrity of their work, inevitably contributing to the safety and durability of the welded structures.

Conclusion

In conclusion, stopping undercut welding and guaranteeing stronger weld joints require a combination of correct welding strategy, selecting the right electrode, preparing the base metal appropriately, and conducting post-weld assessments. By understanding the reasons for undercut welding and applying the essential find out precautions, welders can generate high-quality weld joints that meet market criteria and ensure the structural stability of the welded components.

Undercut welding is an usual welding flaw that takes place when the weld steel stops working to effectively fill the groove and results in a groove-like clinical depression along the weld grain (Preventing weld undercut). Undercutting can be created by various factors, including excessive welding current, high welding rate, improper electrode angle, incorrect electrode size, and poor welding technique

One of the main reasons for undercut welding is an inequality between the welding present and the welding rate. If the welding current is as well high or the welding speed is also quick, the weld steel might not appropriately fill the groove, leading to undercutting.Keeping the right angle and distance in between the welding gun and the work surface is basic when thinking about the significance of picking the right electrode in welding applications.

Report this page